Window Installation? Why it Matters More Than You Think!

This is what you need to know about Window Installation

When it comes to home improvement, windows are often seen as a cosmetic upgrade. But as any seasoned contractor will tell you, it’s not JUST about how a window looks—it’s about how it’s installed. A poorly installed window can lead to a host of problems, from water damage to energy loss. Improper installation can and will lead to a host of issues that in the long run, could potentially rack up costs far greater than the purchase and installation itself. Lets pull back the blinds on windows and why investing in not just high quality windows, but high quality installation is so beneficial to the long term health of your home and most importantly your family.

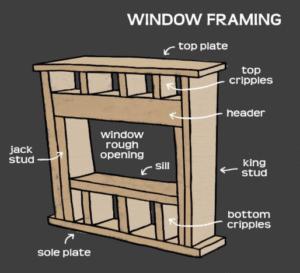

So what does that look like? What is proper installation of windows? It all starts with the foundation of the home. As we have talked about in the proper adherence to code in building decks. The foundation of the home can drastically affect the strength of the structure built on top of it. This structure is called the framing. Traditional lumber framing consists of several different key components that contribute to the rigidity of the opening in the wall where the window will eventually go. Those components are:

- The Header- This is a load-bearing horizontal beam that supports the weight of the wall coming from above the window opening. This helps to transfer the downward force of the wall around the opening, maintaining the structural integrity of the wall. This is usually comprised of doubled up dimensional lumber or engineered wood.

- Jack studs- These are also dimensional lumber that are installed below the header on either side of the window opening. These receive the load transfer from the header and channel it around the window opening to the bottom plate of the window framing.

- King studs- Full height vertical studs that run from the top plate to the bottom plate of the window framing that also bear most of the load being transferred around the window opening.

- Cripple studs- filler studs that fill in the gaps between the top plate and header above the opening and the bottom plate and window sill plate below the opening.

5. Window sill plate- this is a horizontal piece of lumber that frames out the bottom of the windows rough opening.

6. Top plate- this is a horizontal framing member at the top of the wall much like the bottom or sole plate, which does the same thing but is located at the, you guessed it, base or sole of the wall.

7. Rough opening- This is the finished framed out opening where the window unit will be installed after the installation of the proper water mitigation measures.

Adding to the strength of the opening both vertically and laterally is the sheathing. Sheathing, depending on the environment, load requirements, local codes for fire resistance or penetrability from flying debris, can vary greatly in composition, thickness and installation.

Traditionally framed residential homes require something along the lines of sheathing plywood such as OSB or glued, layered wood.

Sheathing, house wrap and seam tape are critical in the waterproofing process of the window openings. All of this layered installation process has to happen in just that, a process. Meaning that some components need to be installed first to achieve the desired outcome. A dry interior. Let’s talk about these components.

House wrap comes in many different brands and different levels of quality. Pictured above is what can largely be considered the industry elite of residential and commercial wrapping solutions, HardieWrap by JamesHardie. Engineered as a moisture barrier, it allows any moisture out, but not anything to penetrate in outside of the penetrations used to secure it to the sheathing and around window and door jambs. These penetrations are then covered with seam tape, or jamb tape, to further waterproof those areas. Every job has a certain way that it can be done so that it stays done. As we have previously discussed in other topics. There is a way to do a job. Then there is the Outback Way.

The Outback Way consists of getting a job done so that it is done completely and that there is a minimal chance or no chance of failure. Continuing this theme for proper installation we now have a component called flashing. Flashing is a metal barrier that offers further waterproofing and water channelling protection that helps to shore against driving rain, debris as well as small insects that may have made it past other components after the installation has been completed.

Contact us today to learn more about our financing options

About Outback Deck, Inc.

Outback Deck, Inc. brings inspiration to outdoor living spaces. We believe if you have an outdoor space, you should WANT to spend time in it. Our commitment to providing the best customer experience and creating outstanding value in your new deck or porch is unmatched in the industry. For more information, please visit www.outbackdeck.net life happens out back